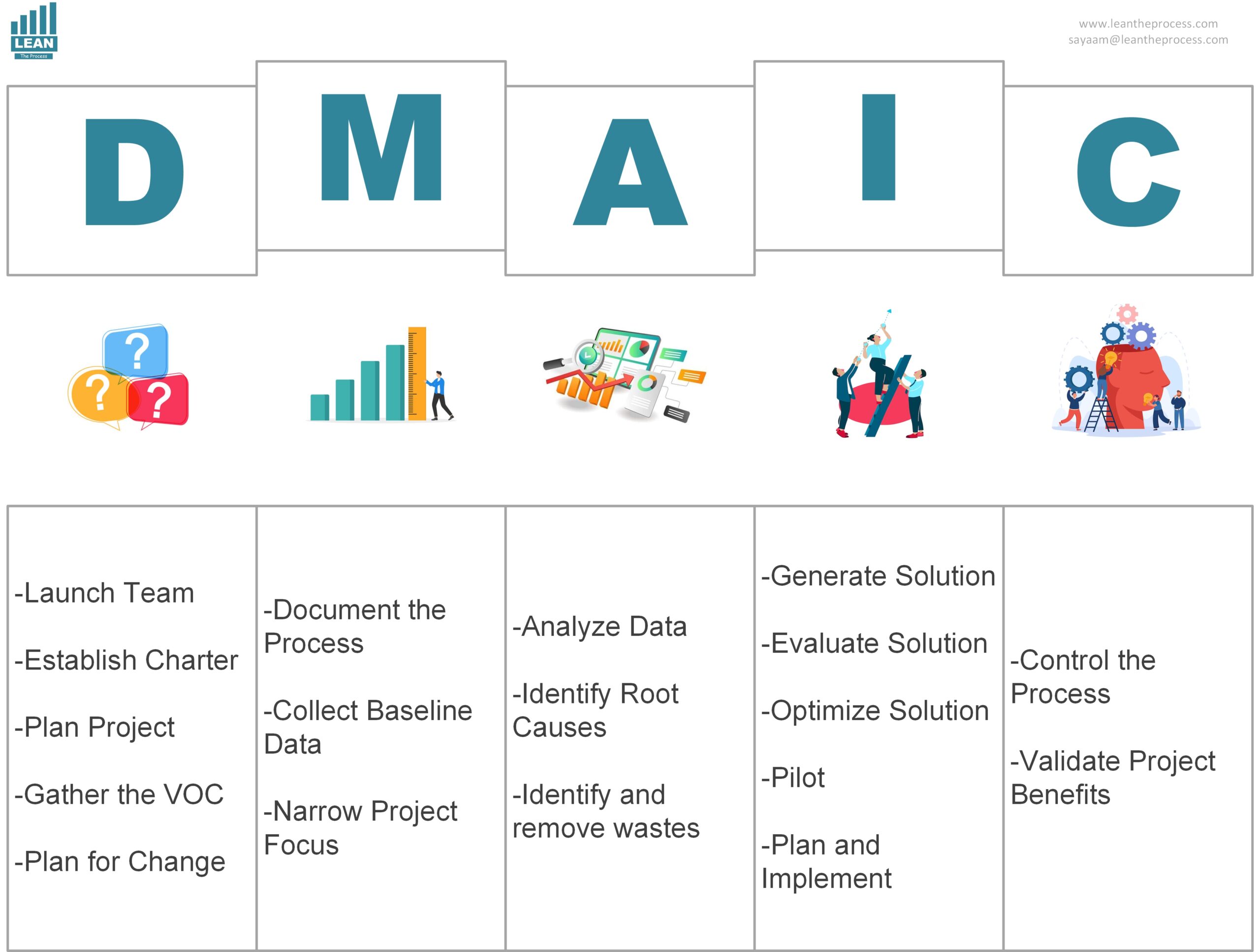

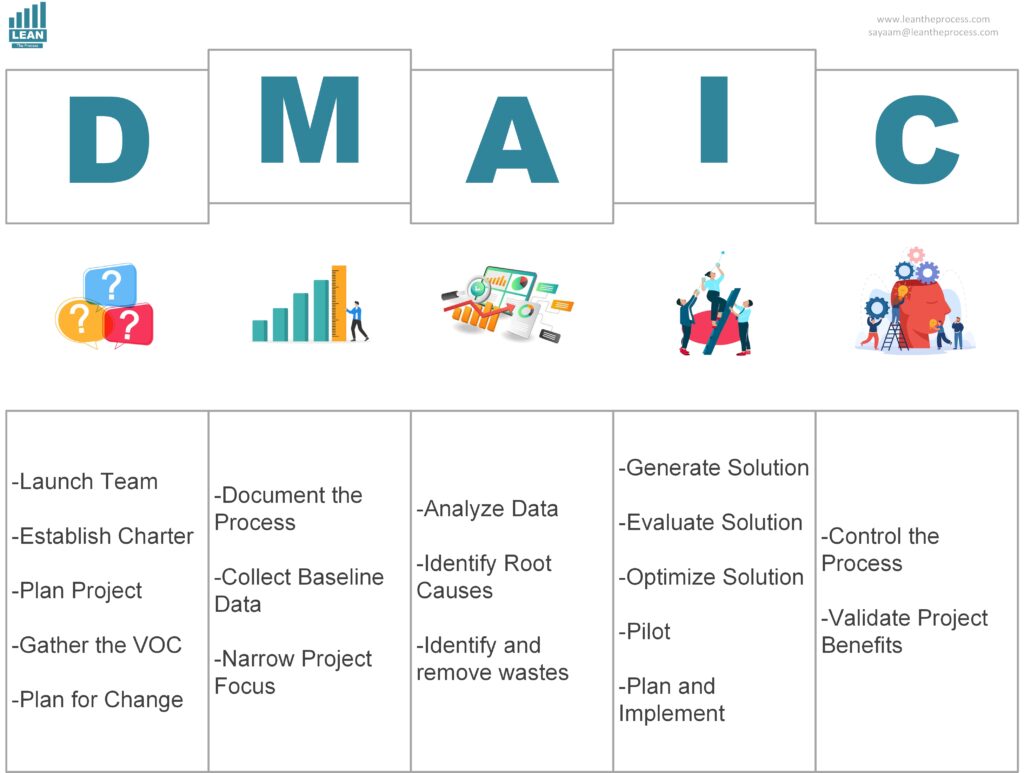

When it comes to process improvement and operational excellence, DMAIC is considered a fundamental part of Lean Six Sigma practices. The acronym DMAIC describes the five structured sequential steps of Define, Measure, Analyze, Improve, and Control. This cycle relies on data to strengthen, improve, and maintain stability in business process and design. DMAIC’s power comes from its structured approach to finding solutions. The methodology relies on the integration of sound statistical techniques and practical tools, avoiding guesswork and intuition to reduce process waste and correct faults. The methodology is best applied when facing issues characterized by complexity, ongoing recurrence, and insufficient understanding, which demand a methodical effort to find underlying causes. Rather than offering fast but temporary improvements, DMAIC guides organizations in making significant and lasting improvements by first systematically determining causes and then validating solutions before widespread application.

Define Phase

It is during the Define phase that the work on the project is launched. It is at this point that the project team makes clear the issue they are aiming to resolve and lays out the boundaries and purpose of the project. The clarity achieved in the problem statement opens up the DMAIC process for effective application throughout. The primary purpose of this phase is to gather VOC data in order to ascertain customer needs and to then translate those findings into quantifiable project targets. To bring clarity to process limits, key players, and project success, teams frequently depend on SIPOC diagrams and project charters. Lack of a well-defined problem statement may lead to off-track activity in later phases, meaning that establishing clarity is particularly essential at this time. Frequently, teams discover that the problem as first understood is actually a consequence of a larger issue, which leads to improved refinement of the project’s objectives.

Get start with your lean six sigma certification https://leantheprocess.com/course-list/

Measure Phase

When the problem has been identified, the subsequent action is to assess the present performance of the process. The main objective here is to assemble data and set a benchmark for evaluating outcomes. Gathering dependable data that precisely illustrates the existing process performance is of utmost importance. Examples of measurements are cycle times, cost, rate of defects, and metrics deemed important for the present challenge. The group specifies which CTQ features must be measured and develops a plan to guarantee the collected data is both uniform and reliable. Many organizations are surprised when data shows deviations from anticipated process performance during this phase. Measuring how accurate and meaningful the data is an important goal, which explains the common use of MSA and Process Capability Analysis tools here. The objective is to assemble data that will be utilized in a meaningful way during subsequent analysis.

Analyze Phase

Following a strong analysis of current results, the Analyze phase prioritizes the discovery of the main sources of the issue. It is at this stage that teams take an in-depth look at data to determine the cause of the problem. Statistical methods, such as regression analysis, hypothesis testing, Pareto charts, and fishbone diagrams, are applied to discover interrelationships and trends. It seeks to shift attention from symptoms toward the actual fundamental factors behind inefficiency or defect. Examining all possible sources of variation often means running brainstorming sessions, drawing process maps, and conducting cause-and-effect analyses. In certain cases, teams opt to perform experiments or conduct simulations in order to confirm their hypotheses. Its main strength is its promotion of assumptive questioning and aversion to premature presumptions. The process encourages everyone involved to make sure all findings are verified with relevant data before taking further action. The analytical effort at this point makes certain that the improvements in the following phase are both effective and well-focused.

Improve Phase

The Improve phase follows root cause identification and is when suggested actions are put into practice. Now, the team generates and checks possible solutions to get rid of the root causes that were previously found. Much of the time, solutions include changes to processes, the introduction of mistake-proofing techniques, the addition of automation systems, or operational modifications, all of which can deliver large results. The aim is to try out suggested solutions and measure their results so that effectiveness can be confirmed prior to large-scale deployment. Risk assessment and improvement optimization are achieved by using techniques including DOE and FMEA. At this stage, special attention is given to nurturing creativity within the team, so that alternatives are explored and tested under real work circumstances. Numerous adjustments in the improvement process may be required to ready the solution for complete implementation. An Improve phase that meets its objectives enhances performance in a way that can be measured and retains those gains in alignment with the customer’s needs and business purpose.

Control Phase

The Control phase is crucial because it guarantees that the benefits accomplished are sustained as time passes. Addressing a problem one time is insufficient. The changes must be integrated into standard practices going forward. Standard operating procedures are developed, training materials are revised, and control charts or monitoring systems are introduced to keep the results consistent. Performance is checked using KPIs to rapidly discover and respond to shifts from normal results. A control plan is organized to make sure that each responsible person adheres to the improved process over time. The phase emphasizes securing the lasting impact of improvements by means of documentation and repeated communication. It is common for organizations to use dashboard tools or automated alerts to keep performance under constant observation. By making sure controls are a regular part of operations, the risk of processes regressing is greatly reduced. In addition, important lessons are recorded and shared enterprise-wide to sustain an atmosphere of ongoing progress.

Become Lean Six Sigma Certified https://leantheprocess.com/course-list/