In today’s industrial revolution, continuous process improvement is key to staying competitive. One of the most widely recognized methodologies for driving efficiency is Lean Six Sigma. At the core of this methodology is the DMAIC framework, a systematic approach used to improve existing processes. Whether you’re looking to enhance product quality, streamline operations, or reduce waste, DMAIC offers a structured approach to problem-solving and process optimization. In this blog, we’ll dive deep into the DMAIC process, breaking down each phase and explaining how it can help your business achieve its performance goals.

What is DMAIC in Lean Six Sigma?

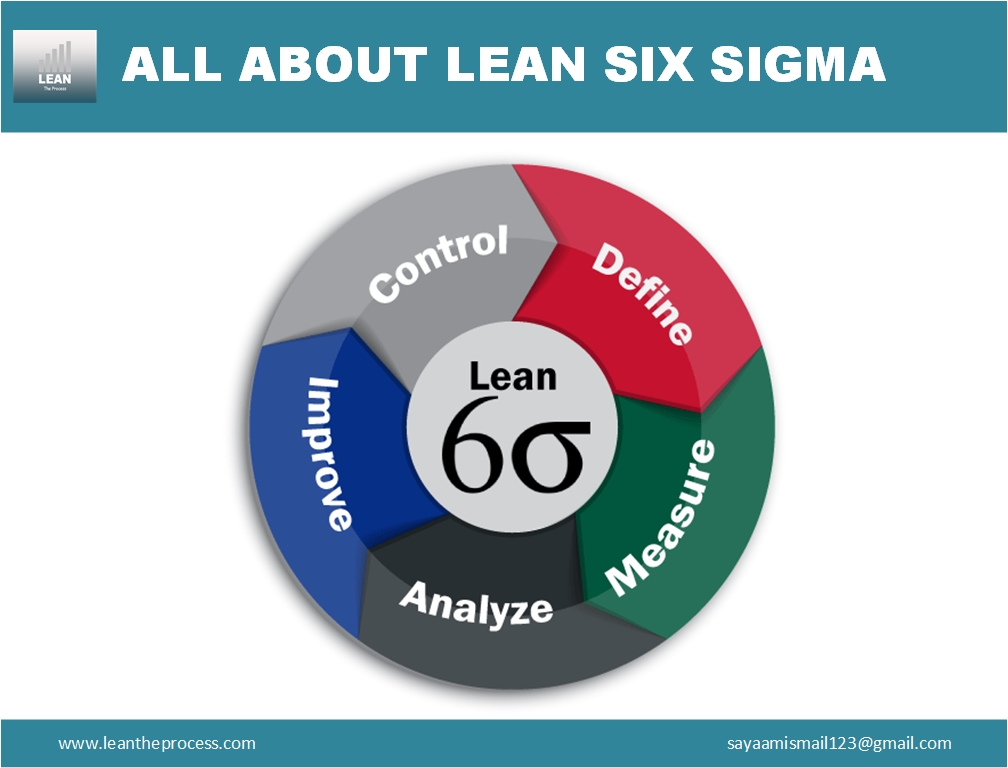

DMAIC stands for Define, Measure, Analyze, Improve, and Control. It’s a data-driven, systematic approach to problem-solving and process optimization. The method is applied in situations where existing processes are underperforming and the goal is to improve quality and efficiency while eliminating waste.

1. Define Phase: Setting the Stage for Success

In the Define phase, the primary goal is to identify the problem clearly. This involves understanding the customer needs, defining the project scope and setting measurable goals. The key activities during this phase include:

- Problem Statement: Identify the issue impacting performance.

- Project Charter: Establish a project plan with clear objectives.

- Voice of the Customer (VOC): Gather customer feedback to understand their needs.

- Team Formation: Assemble a cross-functional team to work on the project.

By defining the problem in clear, measurable terms, this phase sets the foundation for the rest of the DMAIC process.

2. Measure Phase: Collecting Data to Drive Insights

In the Measure phase, the goal is to collect data that will help analyze the problem. Without solid data, it’s impossible to identify root causes and measure improvements. This phase involves:

- Data Collection: Collect data on key process metrics.

- Process Mapping: Create a detailed process map to understand how the process operates.

- Baseline Measurement: Determine the current performance baseline.

Effective measurement ensures that you can track progress, identify variances and provide quantifiable results at the end of the project.

3. Analyze Phase: Identifying Root Causes

The Analyze phase is where the data collected is put to work. The focus here is on identifying the root causes of the problem and understanding process variations. Key activities include:

- Root Cause Analysis (RCA): Use tools like fishbone diagrams and Pareto charts to identify underlying causes.

- Statistical Analysis: Use statistical methods to analyze data and uncover patterns.

- Hypothesis Testing: Test assumptions and validate root causes.

This phase aims to pinpoint the factors that are limiting process performance, so you can target them for improvement.

4. Improve Phase: Implementing Solutions

In the Improve phase, it’s time to make changes based on the findings from the Analyze phase. This phase focuses on implementing solutions that will drive measurable improvements. Key activities include:

- Solution Generation: Brainstorm and identify potential solutions to address the root causes.

- Pilot Testing: Implement solutions on a small scale before full deployment.

- Process Optimization: Apply Lean tools like Kaizen and 5S to streamline processes.

This phase is critical because it involves turning analysis into action, driving real improvements that will positively impact performance.

5. Control Phase: Ensuring Sustainability

The Control phase ensures that the improvements made are sustainable over the long term. Without proper controls in place, there’s a risk that the process will revert to its previous state. Activities in this phase include:

- Control Plan: Develop a plan to monitor ongoing performance.

- Standardization: Standardize best practices to ensure that improvements are maintained.

- Training and Documentation: Ensure the team is trained and that processes are documented for future reference.

By establishing controls, businesses can ensure that improvements are not only achieved but also sustained over time.

Why DMAIC Matters for Your Business

DMAIC provides businesses with a proven framework for achieving process excellence. Whether you’re in manufacturing, healthcare, or service industries, DMAIC helps you:

- Reduce Costs: By eliminating waste and improving efficiency.

- Enhance Quality: Through data-driven improvements that lead to fewer defects.

- Increase Customer Satisfaction: By focusing on the voice of the customer and delivering better value.

Conclusion

Implementing the DMAIC framework can be a game-changer for your business. It helps you systematically identify and solve problems, improve processes, and sustain those improvements for the long term. If you’re ready to take your business to the next level, consider adopting DMAIC as part of your Lean Six Sigma strategy.

By following the DMAIC methodology, you’ll be well on your way to achieving operational excellence and driving continuous improvement.