FMEA (Failure Modes and Effects Analysis) is one of the most effective methodologies of looking proactively into ways of identifying and preventing possible failures that may be caused in products or even processes. Irrespective of whether you work in manufacturing, healthcare, automotive, food and beverage or service industries, FMEA will aid in the determination of potential failure modes, assessment of the consequences and prioritization of corrective measures that will ensure that nothing is passed on to the customer. In this post we are going to discuss what FMEA is, the necessity of it, how to implement it and give a real life example so as to make this concept more practical.

What is FMEA and Why is it Important?

FMEA (Failure Modes and Effects Analysis) is a structured risk management method to enable identification of the point and mode in which a process, product or system may fail and to gain knowledge of the relative impact of the various failures. The technique goes back to the aerospace and defense industries during the 1940s but thanks to its structured process of risk reduction, it became popular in many different industries.

Rather than dealing with the failures once they happen, organizations employ FMEA to envisage risks at the design or development phase. Such proactive strategy will reduce the chances of expensive product recalls, production shutdowns, safety risks and customer dissatisfaction. Moreover, FMEA is frequently used during the time to comply with several quality management standards including ISO 9001, IATF 16949, FSSC 22000, etc. as many of the standards demand documented assessments of risks.

Types of FMEA

FMEA exists in two main forms , Process FMEA (PFMEA) and Design FMEA (DFMEA).

Design FMEA is implemented towards the initial phases of product development. It is directed at possible failures within design aspects- e.g. materials, tolerances or operating conditions. As an example, the DFMEA could be applied in the automotive business where it may evaluate the danger of a braking process given different temperature and pressure circumstances.

Process FMEA, however, is applied in the process of evaluating the manufacturing processes or service delivery. It considers the possibilities of a breakdown of a process because of problems such as human errors, wrong queue settings, or malfunction of equipment. PFMEA is usually employed in the production lines to minimize the scrap, rework and customer complaints.

Benefits of Implementing FMEA in Your Organization

The implementation of the FMEA is associated with rather extensive strategic and operational advantages. Primary, it lowers the chances of failure, thereby increasing the quality of the products together with the satisfaction of the customers. It also enables ongoing effort of continuous improvement since it detects weaknesses in processes that may not be obvious. Besides, FMEA contributes to the cross-functional cooperation, as it is usually associated with the participation of engineering department, quality, production, and even customer services.

FMEA assists financially by reducing spending in scrap, rework, warranties and legal liabilities. When it comes to a regulatory aspect, FMEA-adopting companies are in a superior situation of being able to demonstrate risk-based thinking, which is a key requirement in standards such as ISO 9001:2015. Such self-initiative is not only decreasing the non-conformities in external audits, but it is also increasing the stakeholder confidence.

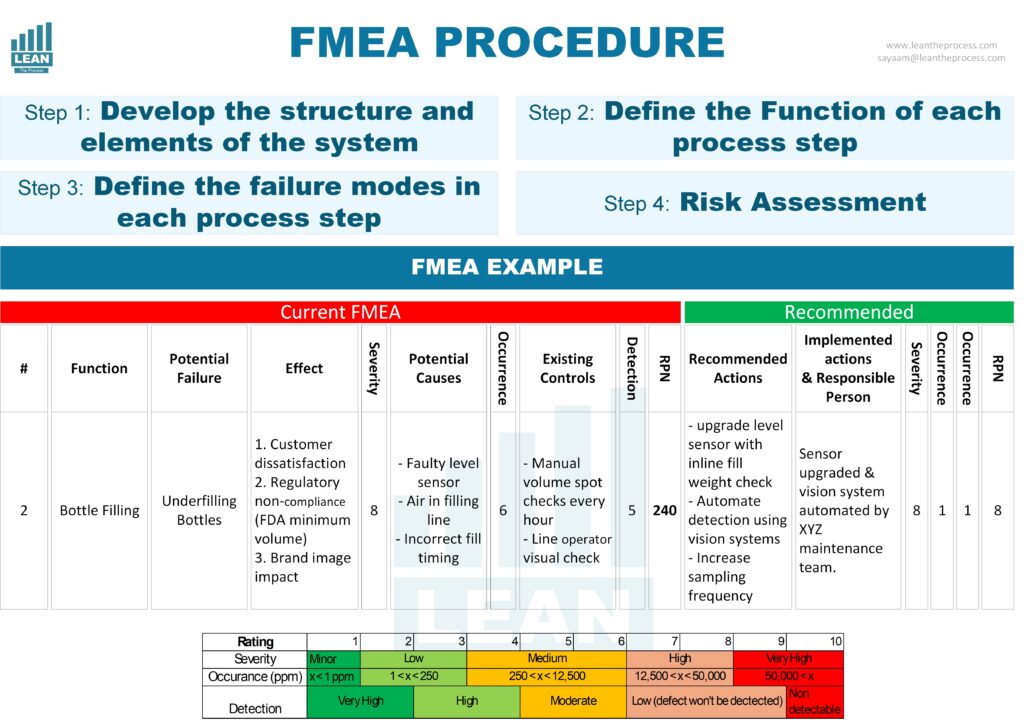

Process FMEA Example (FMEA for Underfilling Bottles in a Soft Drink Bottling Line)

The most significant stage during soft drink manufacturing is the filling of bottles whereby there must be accurate values in the fluid filled into the bottle. The most frequent and possibly dangerous mode of failure in this process is underfilling bottles. The consequences of this problem may be various and they include customer complaints, regulatory infractions (particularly on minimum volume statements), and brand trust loss. The underfilling was among the high-priority risks defined in an FMEA ( Failure Modes and Effects Analysis ) study that was carried out in a carbonated soft drink line.

The impact level of the failure was determined to be 8 out of 10, because it would highly affect the customer satisfaction and compliances with the law. The most common reasons found were failure of level sensor, air trapped on the filling line and improper timing adjustment. Data on past production rates showed that an average of 12 bottles were underfilled in each shift and therefore the failure occurrence rating stood at 6. The existing controls were to consist of hourly manual spot inspection and visual inspection by line operator. But because of the shortcomings of these manual procedures, the rating in the detection was made 5 because of possibility of some underfilled containers to go without detection between inspections. It was determined that the Risk Priority Number (RPN) of this mode of failure must be 240 (SxOxD = 8 x6 x5). This result means that it is necessary to take immediate measures.

As a way of limiting this risk, the proposed steps were: using a more precise inline weight/fill-level sensor, performing more frequent quality inspection, and automating the quality inspection by a vision system. These are done to lessen the chance of occurrence as well as early detection. Since this particular failure mode is targeted in FMEA, through this method the production line will be able to minimize the amount of wastes of the product, enhance quality checks and also guarantee that the final customer has a more enjoyable experience.