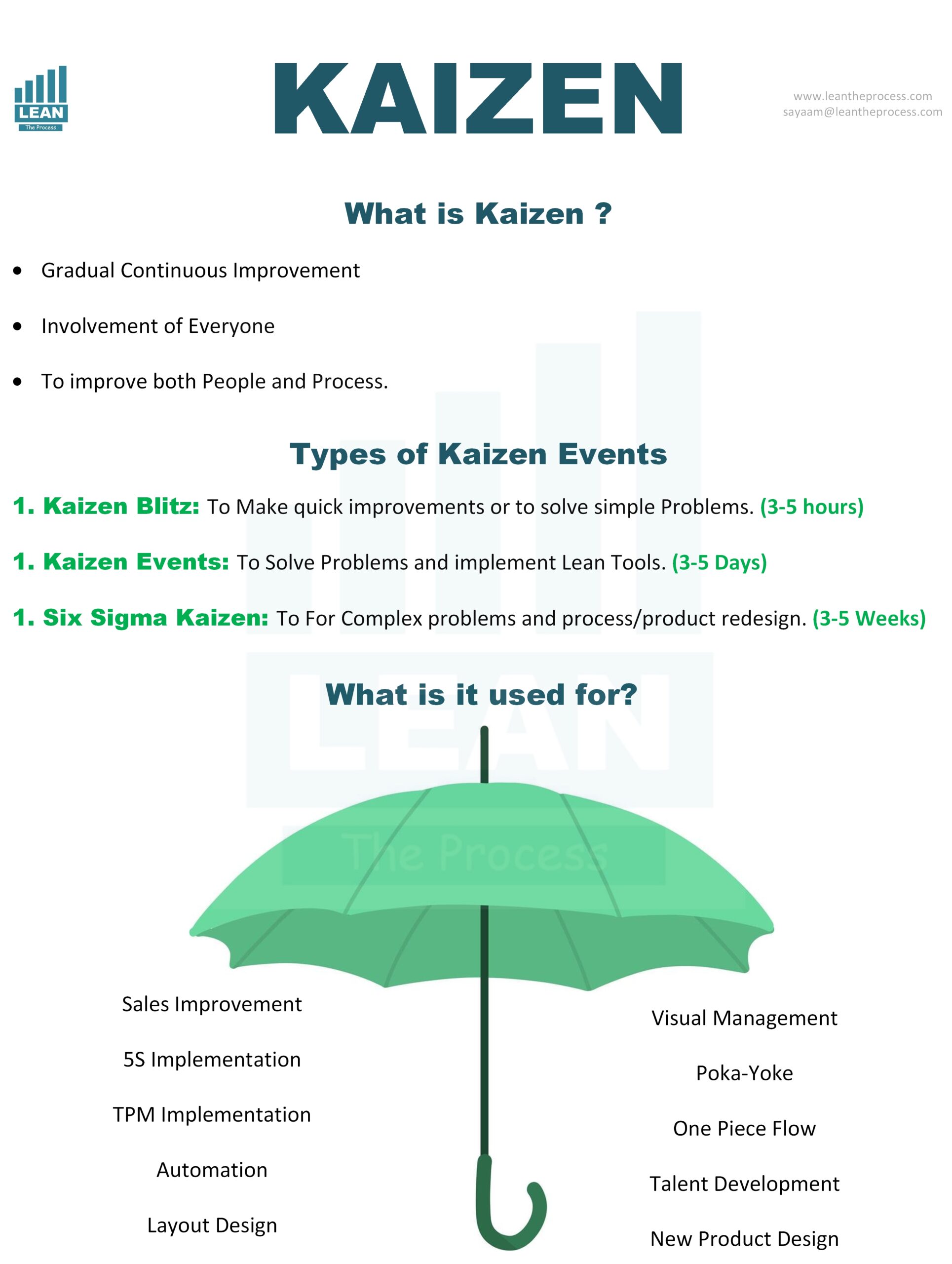

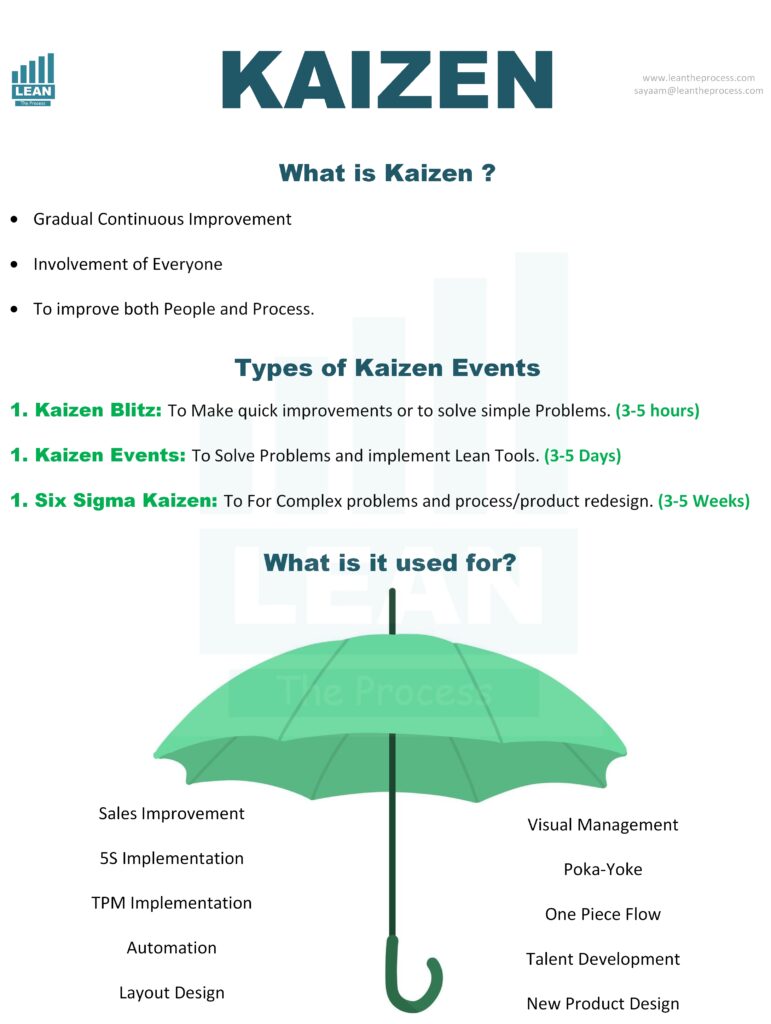

Being competitive in our quick-changing business world requires firms to focus on ongoing improvement. Therefore, Kaizen was developed as a strategy for improvement in Japan, where it is called ‘continuous improvement’ or ‘change for the better.’ It is more than just a trendy phrase; organizations in many areas rely on it as an effective strategy to raise productivity, cut waste, and nurture continual organizational learning.

Why Kaizen ?

The central aim of Kaizen is to refine organizational approaches, raise efficiency, and amplify overall quality using ongoing, small-scale transformations. The use of Kaizen can be found in a variety of industries including manufacturing, healthcare, logistics, and services, where it advocates incremental changes led by employees, rather than major organizational changes. The method stands out by effectively minimizing waste—muda—including time, materials, and procedural processes. Because Kaizen enhances both workflow management and communication, it simplifies organizational operations and simultaneously encourages employees to be more engaged by letting them take part in finding solutions. In addition, continually working toward improvement leads to better customer satisfaction by ensuring lasting quality increases. Integrated with Lean and Six Sigma approaches, Kaizen is significant in propelling operational quality and championing ongoing improvement Inside organizations.

Kaizen Events

Kaizen largely represents a corporate culture of incremental improvement, but is often delivered through focused events called Kaizen events or blitzes. The duration of these events is typically three to five days and their focus is on particular processes that require development. Bringing together workers from different functions allows organizations to rapidly spot issues, find the fundamental causes, and implement resolve-then-and-there solutions. Usually, the setup of a Kaizen event resolves into several major phases. In the planning stage, the goals and boundaries are made explicit; observation ensures that current operations are carefully monitored and data are gathered; the analysis phase targets the identification of waste and inefficiencies; implementation brings about quick process improvements; and review measures the impact of changes and institutionalizes those improvements that offer value. It is the combination of readily accessible results and the promotion of teamwork that distinguishes Kaizen events and empowers those involved. By transparently showcasing the value of ongoing process enhancement on a manageable scale, these events act as drivers for larger organizational development.