In today’s competitive business environment, companies are always looking for ways to improve efficiency, minimize costs and enhance customer satisfaction. Lean Six Sigma has become one of the most powerful methodologies to achieve these goals. By combining the principles of Lean, which focuses on eliminating waste and Six Sigma, which focuses on reducing variation, Lean Six Sigma helps organizations streamline processes and achieve operational excellence.

What is Lean Six Sigma?

Lean Six Sigma is a integrated methodology that combines the tools and techniques of both Lean and Six Sigma to drive continuous improvement. While Lean focuses on improving flow by eliminating non-value-added activities (waste), Six Sigma aims to enhance process quality by reducing defects and minimizing variability. When these two methodologies are used together, they create a robust framework for improving business processes, making them more efficient and effective.

The Core Principles of Lean Six Sigma

Lean Six Sigma operates on several core principles:

- Focus on the Customer: The primary goal is to deliver maximum value to the customer. Understanding customer requirements and aligning processes to meet these needs is crucial.

- Identify and Eliminate Waste: Lean identifies seven types of waste (Muda) in processes: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion and extra processing. Lean Six Sigma aims to minimize or eliminate these to streamline operations.

- Reduce Variation and Defects: Six Sigma targets the reduction of variability in processes. By using statistical tools, it identifies the root causes of defects and ensures that products or services meet customer expectations consistently.

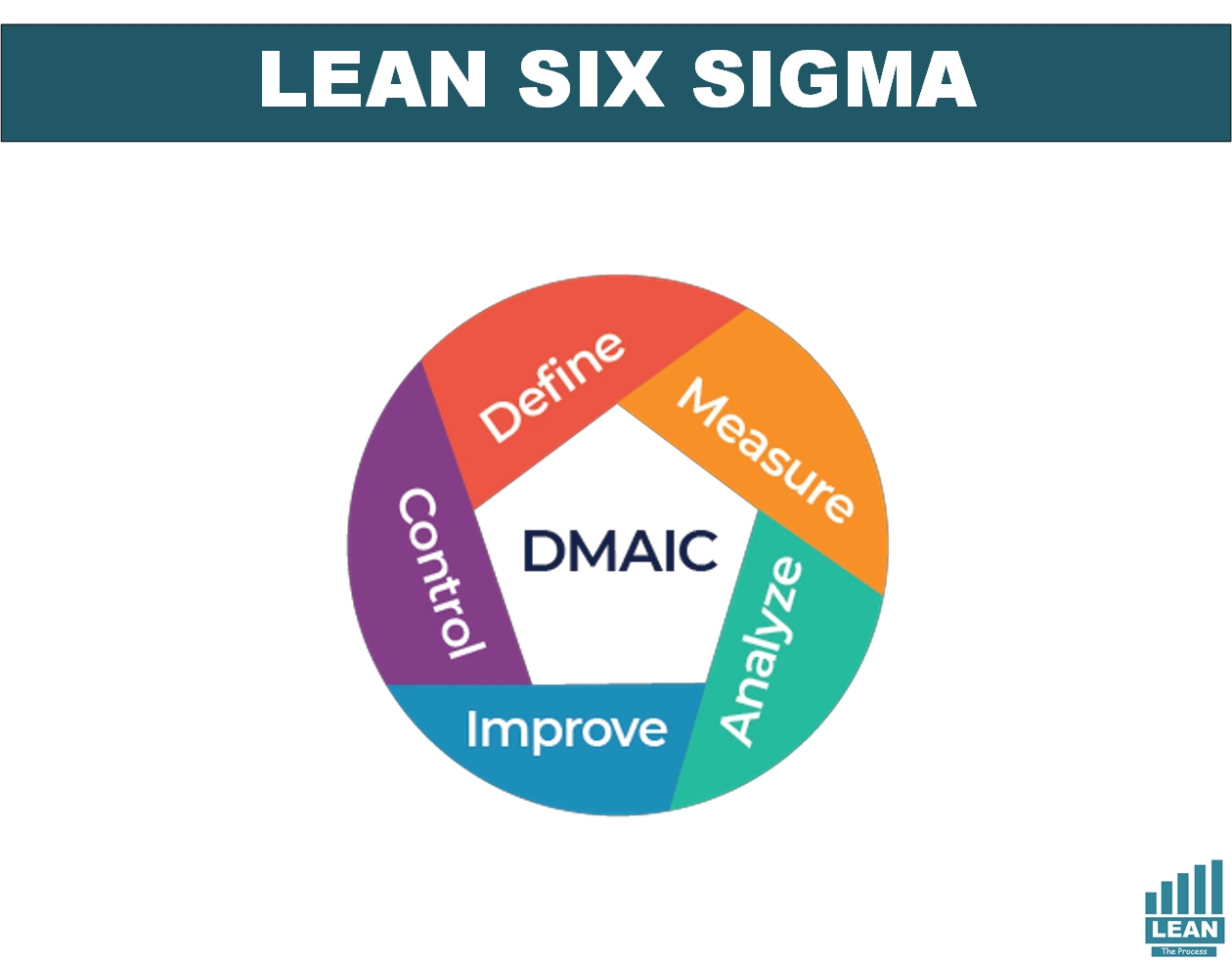

- Data-Driven Decision Making: Lean Six Sigma uses data and facts to make informed decisions. Tools like DMAIC (Define, Measure, Analyze, Improve, Control) are used to identify and solve problems based on solid data rather than intuition.

- Empower the Team: A key aspect of Lean Six Sigma is involving employees at all levels in the improvement process. When teams are empowered, they contribute to finding solutions that improve efficiency and eliminate waste.

The DMAIC Methodology

One of the most widely used frameworks within Lean Six Sigma is DMAIC, which stands for:

- Define: Identify the problem and the project goals.

- Measure: Collect data and establish baselines for the current performance.

- Analyze: Identify root causes of the problems by analyzing the data.

- Improve: Develop and implement solutions to address the root causes.

- Control: Monitor the improvements to ensure sustainability over time.

The Benefits of Lean Six Sigma

- Improved Efficiency: Lean Six Sigma helps eliminate waste and reduce variation, leading to streamlined processes and faster production times.

- Cost Reduction: By removing inefficiencies, companies can lower operational costs, improve profitability, and reduce the cost of poor quality.

- Better Quality: The emphasis on reducing defects ensures higher quality products and services, leading to increased customer satisfaction.

- Employee Engagement: Lean Six Sigma empowers employees to take ownership of process improvements, leading to a more engaged workforce.

- Sustainability: The “Control” phase of DMAIC ensures that improvements are sustained, preventing processes from reverting to their previous state.

Lean Six Sigma in Action

Many companies across various industries have successfully implemented Lean Six Sigma. For example, General Electric and Motorola have used it to enhance production quality, reduce defects, and improve customer satisfaction. In healthcare, hospitals have applied Lean Six Sigma to reduce patient wait times and improve the accuracy of medical records, resulting in better patient care.

Lean Six Sigma Certifications

For professionals seeking to gain expertise in Lean Six Sigma, certification programs are available at multiple levels:

- Lean Six Sigma Yellow Belt: Basic understanding of Lean Six Sigma principles.

- Lean Six Sigma Green Belt: Intermediate level, leading improvement projects within their area.

- Lean Six Sigma Black Belt: Advanced level, overseeing large projects and coaching Green Belts.

- Lean Six Sigma Master Black Belt: Expert level, focusing on strategy and mentoring Black Belts.

Conclusion

Lean Six Sigma is a powerful, results-driven methodology for organizations looking to enhance efficiency, reduce waste, and improve quality. By focusing on customer needs and using a data-driven approach, businesses can achieve significant gains in both productivity and profitability. Whether you’re in manufacturing, healthcare, or service industries, Lean Six Sigma provides a robust framework for achieving continuous improvement and operational excellence.