Organizations are continually being pushed by the hyper competitive business environment to decrease cost, remove waste and enhance customer contentment in the contemporary business environment. That is where Lean Six Sigma comes in and makes the changes. As a desire to advance your career by getting a certification in Lean Six Sigma or the need to find a method of streamlining the work in your organization, the realization of this effective way of accomplishing much can make the difference in any industry.

What is Lean Six Sigma?

Lean Six Sigma is a composite management approach integrating the waste lean capacities of Lean with the defect Six Sigma task. The essence of it is to enhance effectiveness in the process, reduce variation in the structure and produce value to the customer utilizing less resources.

Lean aims at removing the non-value-added operations (waste) and Six Sigma unlikely to be of use to the author. They are used in combination to give a defined data-driven process of process improvement which is the Lean Six Sigma methodology.

Why Choose Lean Six Sigma Certification?

A Lean Six Sigma certification qualifies your skills and knowledge in rooting out inefficiencies, resolving complicated business issues and in leading continuous improvement projects. It will increase your professional credibility and will provide access into leadership positions at quality management level, operations, logistics and much more.

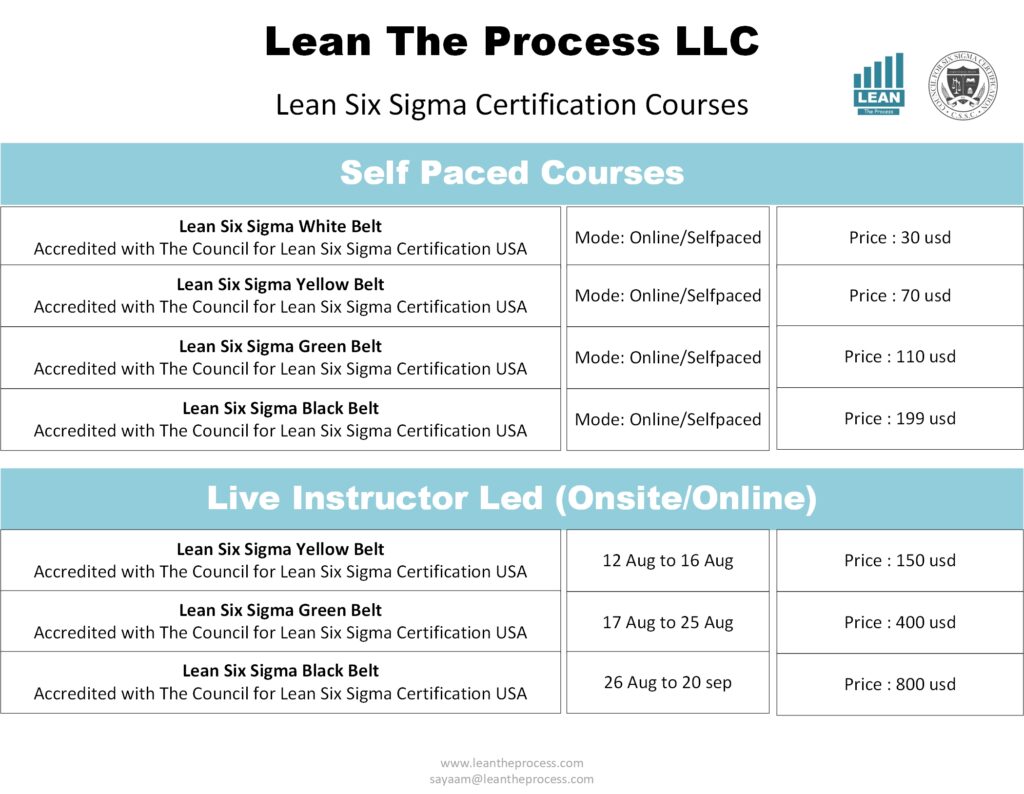

Professionals can be sought at different levels of certification:

- Lean Six Sigma Yellow Belt: This is the one that suits new learners; it is basic concepts and tools.

- Lean Six Sigma Green Belt: This one is appropriate to leaders of small to medium-sized initiatives.

- Lean Six Sigma Black Belt: Designed to employees that deal with large-scale improvement project and coach other team members.

All the levels allow greater knowledge of Lean Six Sigma concepts including value stream mapping, DMAIC (Define, Measure, Analyze, Improve, Control), root cause analysis and process capability analysis.

Lean Six Sigma Training: Building Skills for Real-World Impact

Having trained in Lean Six Sigma enables people to obtain the necessary knowledge and tools to enhance the business processes. Individually, the most effective arcane programs incorporate interactive simulations, case studies and other real world projects where participants can integrate theory into actual practice.

To give an example, training on Lean Six Sigma Green Belt would enable you to apply tools such as the Fishbone Diagram, the Pareto Chart, the Control Chart and the Process Maps. The tools play a critical role in the process of establishing bottlenecks and measurement of variability in processes.

In the meantime, Lean Six Sigma Black Belt training goes further into obtaining an in-depth understanding of advanced tools of statistics, leadership skills, and change management efforts. Certified Black Belts usually manage cross functional teams and they engage in strategic decisions.

Real-Life Lean Six Sigma Examples

It is impossible to list all the examples of Lean Six Sigma across industries: healthcare, manufacturing, IT, logistics, and finance. A hospital can use DMAIC to circumvent the time taken by patients to be admitted in the hospital and a manufacturing factory can also use Statistical Process Control (SPC) to minimize the number of defects.

General Electric is one of the most characteristic cases when by implementing Lean Six Sigma tools this company saved billions of dollars by integrating the tools into its functions. Amazon and Toyota are no exception since they have deployed these methodologies to improve efficiency, reduce expenses and offer their customers the best experiences.

Lean Six Sigma Tools That Drive Transformation

One of the most significant aspects of any Lean Six Sigma training is the mastery of the tools that will allow identifying the root cause and making very long-lasting improvements. Some of the common Lean Six Sigma tools are:

- DMAIC Framework

- Value Stream mapping

- 5 Whys

- Control Charts

- Process Capability Indices (Cp, Cpk)

- Failure Modes and Effects Analysis (FMEA)

The tools facilitate teams in using data to make their decisions instead of depending on intuition. When applied correctly, they help to reveal the inefficiencies that were not previously identified and direct the way to improvement that is measurable, both with respect to financial and operational efforts.

The hallmarks of efficiency, quality and customer satisfaction are what make the difference in a profitable world and that is where Lean Six Sigma offers a tried and tested path to operational success. Investing in Lean Six Sigma certification and Lean Six Sigma training programs could be a tipping point, be it climbing the corporate ladder or streamlining the operations of your organization.

Practical Lean Six Sigma examples, proven tools and thought principles will make you a change agent in the workplace. Begin your adventure now and select the appropriate belt- Lean Six Sigma Yellow Belt, Green Belt, or Black Belt training course, and become a part of an international community of quality improvement experts who are changing industries one project at a time.