The mission of going after the waste is one of the main aspects of Lean Manufacturing. Waste or the muda in Japanese is any activity or process that is consumptive in nature and does not contribute value to the final customer. When these wastes are identified and eradicated, the organizations can automate their operations, it can cut on costs and also enhance customer satisfaction. The following blog post discusses the 8 kinds of waste in Lean Manufacturing, as well as providing examples used in the real world and elimination strategies to aid you in delivering continuous improvements throughout your processes.

1- Transportation – Unnecessary Movement of Materials

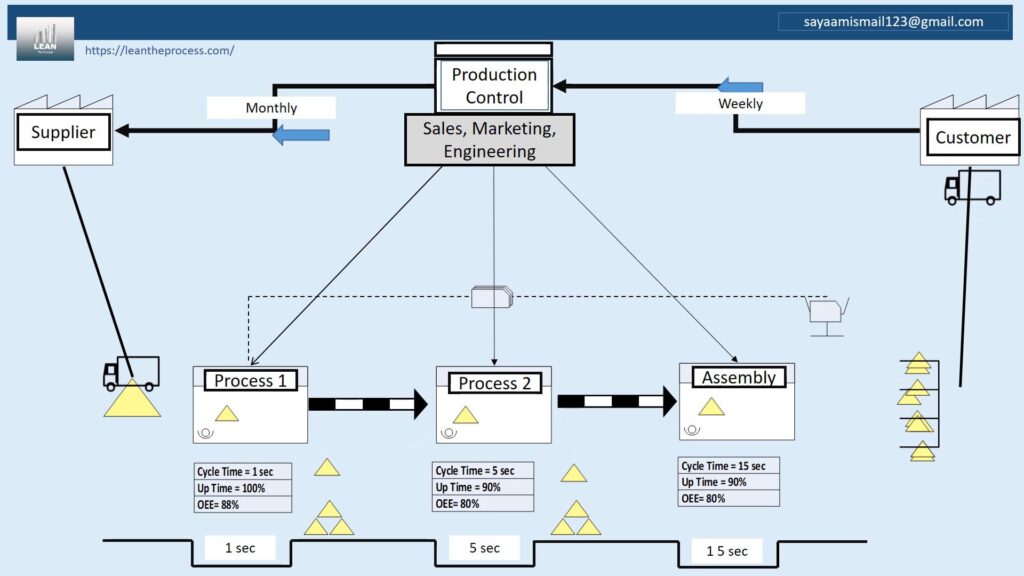

Transportation waste happens when products or materials or tools are transported in excess than what is required within a facility. Whenever a product is moved, it adds on to the danger of destruction, misplacement, or break given that no value is added to the product. The usual culprits are bad plant layout, non-standard material flow or batch processing. To improve efficiency removing wastes that involved transportation, use value stream mapping in order to optimize work flow and design cellular layouts to cut the distance of travel between work stations.

2- Inventory – Excess Products or Materials Not Being Processed

Any raw materials, work in progress (WIP) or finished goods that are not being actively utilized form the inventory waste. Unnecessary inventory occupies capital, obstructs valuable floor space and may bring about problems like product obsolescence, damage and flaws during handling. Lean also tries to make what is necessary, when it is necessary, by such means as Just-In-Time (JIT) type of production and the Kanban system, to control flow and to reduce over-productions.

3- Motion – Unnecessary Movements of People

In contrast, the concept of motion waste is related to physical fatigue and inefficiency brought to a company by employees moving around doing absolutely nothing. This involves bending, reaching, walking or searching tool. This movement does not only make productivity go down but also makes one more likely to experience an injury. The organization of tools in the workplace, standardized tasks, the design of processes during which human movement is considered are the sources of reducing motion waste through workplace ergonomics, and 5S methodology.

4- Waiting – Idle Time Due to Delays

Waiting waste is a waste that arises when the machines or the staff is waiting because there are delays encountered in the production process. This may be due to equipment outage, supply chain disruptions or poor scheduling. Each of the waiting minutes is the squandered chance to generate value. Some of the solutions are Total Productive Maintenance ( TPM ) to minimize failure of equipment, takt time balancing to synchronize the processes and cross-training of workers to allow flexibility of tasks.

5- Overproduction – Producing More Than Needed

The most damaging waste present in the Lean Manufacturing is usually overproduction. It causes over stocking, extra burden of storage and concealed quality problems. Overproduction, overproducing at an inappropriate point in time, or overproduction in excess of customer requirements burns a lot of resources and is a sign of inefficiencies. Fight this waste by making production conform to real demand with pull systems, demand forecasting and smaller batch sizes.

6- Overprocessing – Doing More Work Than Necessary

Where a product is made more complex or refined than the customer needs, it is over processed waste. This may entail empty polishing, cross-checking or excessively sophisticated gadgets or technology. It is usually as a result of either bad process design or vague customer demands. To get rid of overprocessing, pay attention to standardized work, and clarify quality expectations and use root cause analysis to find out what extraneous steps you have in your processes.

7- Defects – Errors That Require Rework or Scrap

Defects make a waste of both material and labor but also break the customer trust and brand image. These are characterized by all products or services that do not match quality standards. The total cost of defect is multiplicative due to defect propagation through the process. Lean relies on Poka-Yoke (error-proof), Statistical Process Control (SPC) and continuous improvement of quality to avoid defects and perform right-first-time.

8- Unused Talent – Underutilized Human Potential

Unused talent is one of the most commonly added wastes in the contemporary Lean thinking; it amounts to the inability to take advantage of employees and utilize their creativity, skills and ideas to make improvements. Organizations lose out on ideas and innovation when members are not given freedom, and motivated to share. Activate a culture of Kaizen (continuous improvement), train them and engage employees in issues concerning solving problems, enabling unique potential to be released.

Insights into the factors of the 8 wastes as well as how to eradicate them in perfecting a Lean Manufacturing operation come in handy in forming a more adaptable, effective, and competent organization. From the point of view of a manufacturer, service provider or one part of a supply chain; eliminating these wastes and managing them in an organized way can result in tremendous quality, cost and delivery enhancements. The application of Lean tools such as 5S, value stream mapping, TPM, and Kanban, among others, does not only assist the organization in disposing of waste but also defines a culture of constancy. Begin your Lean story today and turn waste into opportunity and remember in Lean thinking all steps must add value.