In today’s competitive business landscape, organizations are constantly seeking ways to eliminate waste, reduce errors, and optimize processes. Lean Six Sigma has emerged as a gold-standard methodology for achieving these goals, and the Lean Six Sigma Green Belt certification is a pivotal credential for professionals aiming to lead process improvement initiatives. Whether you’re in manufacturing, healthcare, finance, or tech, understanding the role of a Green Belt can unlock opportunities to drive efficiency, enhance quality, and deliver measurable value to your organization.

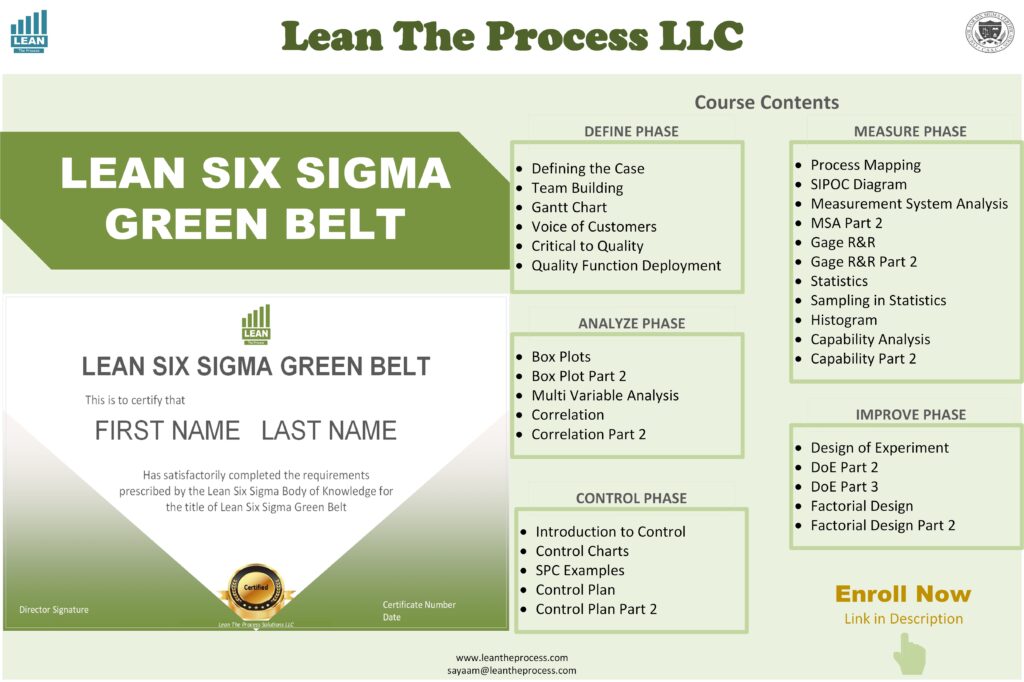

Enroll Now Lean Six Sigma Green Belt !!

What is Lean Six Sigma Green Belt?

Lean Six Sigma combines two powerful methodologies: Lean (focused on eliminating waste and streamlining workflows) and Six Sigma (centered on reducing defects and process variation). A Green Belt practitioner operates at an intermediate level, bridging the gap between entry-level Yellow Belts and advanced Black Belts. Green Belts are often project leaders who apply Lean Six Sigma tools to solve complex problems, mentor team members, and contribute to organizational goals. They are trained in the DMAIC framework (Define, Measure, Analyze, Improve, Control), which provides a structured approach to problem-solving.

Unlike Yellow Belts, who assist with small-scale projects, Green Belts lead initiatives that require deeper statistical analysis and cross-functional collaboration. They work under the guidance of Black Belts but have the autonomy to manage projects from start to finish. This certification is ideal for managers, engineers, and quality assurance professionals looking to formalize their process improvement expertise.

Enroll Now Lean Six Sigma Green Belt !!

Why Pursue a Lean Six Sigma Green Belt Certification?

Organizations across industries prioritize hiring Lean Six Sigma Green Belts because they deliver tangible results. According to industry reports, companies implementing Lean Six Sigma methodologies save an average of $230,000 per project. Green Belts play a critical role in achieving these savings by identifying bottlenecks, reducing cycle times, and improving customer satisfaction.

For professionals, certification opens doors to higher-paying roles. A Green Belt credential signals to employers that you possess the skills to lead data-driven projects, communicate with stakeholders, and align improvements with business objectives. Industries like healthcare use Green Belts to reduce patient wait times, while manufacturing sectors rely on them to cut production costs. The versatility of Lean Six Sigma ensures its applicability in virtually any field.

Key Benefits of Lean Six Sigma Green Belt Training

- Enhanced Problem-Solving Skills: Green Belts master tools like root cause analysis, Pareto charts, and process mapping to diagnose issues systematically.

- Career Advancement: Certified professionals often see salary increases of 10–20% and qualify for roles such as Operations Manager, Quality Analyst, or Supply Chain Specialist.

- Organizational Impact: By reducing defects and waste, Green Belts contribute directly to profitability and customer satisfaction.

- Global Recognition: Certifications from bodies like ASQ, IASSC, or CSSC are respected worldwide, making Green Belts competitive in international markets.

How to Earn Your Lean Six Sigma Green Belt Certification

The certification process typically involves:

- Training: Complete 40–60 hours of coursework covering DMAIC, statistical tools, and Lean principles. Many institutions offer online or in-person options.

- Exams: Pass a proctored exam testing your knowledge of core concepts.

- Project Work: Lead or participate in a real-world project demonstrating your ability to apply Lean Six Sigma methodologies.

While prerequisites vary, most programs require foundational knowledge of process improvement. Popular certifying bodies include the American Society for Quality (ASQ) and the International Association for Six Sigma Certification (IASSC).

Essential Lean Six Sigma Green Belt Tools and Techniques

Green Belts leverage a toolkit of methodologies to drive improvements:

- DMAIC: The backbone of Six Sigma projects.

- Control Charts: Monitor process stability over time.

- Fishbone Diagrams: Visualize root causes of problems.

- 5S Methodology: Organize workspaces for efficiency.

- Regression Analysis: Identify relationships between variables.

Mastering these tools enables Green Belts to quantify issues, test solutions, and sustain improvements long-term.

Enroll Now Lean Six Sigma Green Belt !!

Career Opportunities for Certified Green Belts

Certification can lead to roles such as:

- Process Improvement Manager

- Quality Assurance Lead

- Supply Chain Analyst

- Operational Excellence Consultant

Industries like automotive, aerospace, and IT actively recruit Green Belts to maintain competitive edges. With experience, many professionals advance to Black Belt roles or transition into executive positions.

Conclusion

A Lean Six Sigma Green Belt certification is more than a resume booster—it’s a career accelerator. By equipping you with the skills to lead transformative projects, it positions you as a valuable asset in any industry. Whether you’re aiming to reduce costs, improve quality, or drive innovation, Green Belt training provides the framework to turn challenges into opportunities.

Investing in this certification not only enhances your professional credibility but also empowers you to make a lasting impact on your organization’s success. Ready to take the next step? Explore accredited programs today and join the ranks of elite process improvement experts.

Enroll Now Lean Six Sigma Green Belt !!